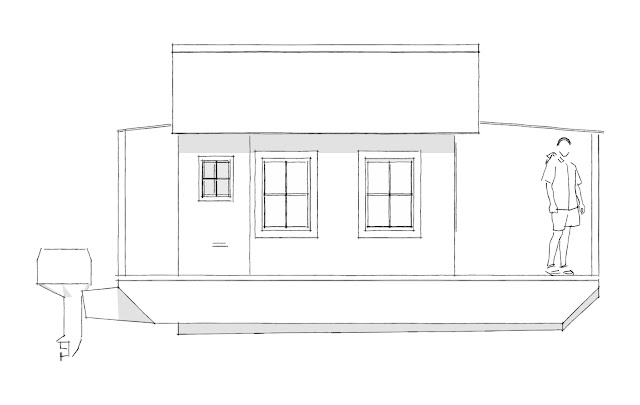

My modifications look like this:

Here are the details I didn't mention in my last musings about the cabin. It always surprises me that finish details often end up having a bearing on the framing of a structure.

Wall Construction

Cabin wall exterior finish: Board and baton (with beautiful ancient redwood)

Cabin wall interior finish: None, boards exposed insideThe cabin is almost two foot lower than the deck. Doors open outward at the top of stairs at deck height -- or maybe they should open inward. I will bring the studs down into the hull to secure them.

I was fretting about the wall design, whether to use 2x2s, 2x3s or 2x4s. I was worried about the wall being burly and strong enough to hold the cabin together, but that's just because of my history as a home builder and familiarity with standard stud construction.

In standard frame construction, I imagined the 2x4s forming little natural nooks inside the cabin, that with a cabinet door could hold the innumerable things that clutter up a boat. Broom, fishing poles, gaff, a million other things.

Chicken John, always ready with an opinion, opined thusly:

"I'm not looking at your design. I didn't read the other comments. Whatever it is you are building it's too heavy. After your 5th revision and you've got your weight down to less then 800 pounds, then we can start talking about the simple fact that whatever is on top of the water you need kinda the same thing under the water. Or you will be punished. Get an apple. Bite into it, deliberately Understand the leverage that your teeth are using. Bite again, even slower. Identify all the physics involved. All the muscles. The sharpness of the tooth, the rigidity. Feel when the apple surrenders to the teeth. Then ask when you boat surrenders to which force? And remember that the kayak is the result of 10,000 years of nautical design."Chicken poetically argues for lighter construction on the topside. So I guess steel armor is right out. I heard others, including the boat's designer Glen L. Witt, similarly expressing concern about weight.

My friend Scott was worried about the weight of the board and baton, but not the sheer strength:

"Boat and batten convey a surprising amount of sheer strength. I'm not so worried about diagonal bracing; and a pair of X-crossed cables could provide lightweight sheer if needed. There's also two feet of stud locked to the hull that's providing sheer, and it's locked in a hole in the deck. It's not going to parallelogram no matter what you make it out of."

Bob on the Shantyboat list offered some great suggestions regarding wall width, insulation, and construction technique.

If you are going to use 2-bys I would use 2x3's perpendicular. You would still have some space for small jars, containers, etc. I have done that in a Tiny House build, leaving the inside open and gluing in more horizontally for shelves. Works great. I would make any shelving easily removable and live with it that first year with your heat source. That way should you decide insulation would be better you can remove them easily to make insulating easier.I will probably do board and batton secured every two feet to spacers without plywood. This is ancient redwood and having that redwood facing in will feel sweet. Only worried a little about water/weather proofing, but there is always construction adhesive and caulk.

Roof Construction

Roof finish: Corrugated metal

The cabin will have a gabled roof and yes, I know that it's totally absurd on a boat for a number of reasons, including height, weight, and wind resistance. However, I really appreciate the aesthetics It is this absurd vision, in fact, that inspired me to build a shantyboat.

Impracticabilities aside, a gabled roof is really quite practice in a number of ways. Lots of storage space, an overhead bunk can fit in the gable, easy to hang stuff from the rafters. It feels big and beautiful and homey.

The roof will be gabled fore and aft. This gives a view forward from the bunk through a small window in the gable. It also keeps the height lower at the edges most likely to have a brush with overhanging trees.

I'll be skimping as much as possible on the roof to save weight.

- 1x6 roof center beam

- 2x4 rafters on 24 inch centers (to support corrugated metal)

- 2x4 cross ties on 24 or 48 inch centers, to support an overhead bunk

Perhaps that gives you a little better idea how things will likely be constructed, and what kind of self-imposed constraints I am working with.